Have you ever dreamed of crafting a stunning underwater landscape by creating your DIY Aquarium Rocks that mirror the awe-inspiring beauty of the ocean’s depths? Imagine creating a vibrant, life-supporting reef aquarium that becomes the centrepiece of your space and a sanctuary for its inhabitants. The journey begins with choosing the suitable materials, a critical step in shaping your aquatic masterpiece’s foundation. Let’s embark on this transformative adventure together, where every grain of sand and drop of cement holds the promise of a thriving marine ecosystem.

Key Takeaways

- Selecting the Right Cement: One of the key takeaways is the importance of choosing the correct type of cement for building aquarium structures. Portland cement, mainly white Portland cement, is recommended due to its lack of additives that could harm aquatic life. Using only cement that is free from toxic substances and safe for use in marine environments is crucial. This choice ensures the longevity of the structures and the safety of the aquarium’s inhabitants.

- Non-toxic Aggregates and Safe Colorants: Another vital point is the selection of non-toxic aggregates and safe colourants to create natural-looking and environmentally friendly rocks. Aggregates should be chosen based on their inert properties and compatibility with marine life, avoiding any that can alter the water’s chemistry. When adding colour to your DIY rocks, using iron oxide pigments or other non-toxic dyes can enhance your aquascape’s aesthetic appeal without jeopardising the aquarium ecosystem’s health.

Begin your journey with our comprehensive guide, “Introduction to DIY Cement Rocks for Reef Aquariums: Enhancing Your Aquascape”. This pillar post is your first step towards creating a stunning, natural-looking underwater world that thrives. Explore the complete article and unlock the secrets to enhancing your aquascape with custom, eco-friendly structures that will captivate.

Understanding the Basics of Cement and non-toxic Aggregates

Creating a thriving reef aquarium requires understanding the marine ecosystem and the materials used to construct its landscape. Among these, cement and aggregates play pivotal roles. Let’s delve deeper into the types of cement and aggregates that are safe for aquatic life, ensuring your DIY rocks contribute positively to your underwater haven.

Understanding Cement Types and Their Implications – Safe Aquarium cement

- Hydraulic vs. Portland Cement: Portland cement is an essential ingredient of concrete, mortar, and most non-specialty grout, and it becomes a binding material when mixed with water and aggregates. It’s classified as “hydraulic” because it can set and harden upon reaction with water, even underwater. However, commercial hydraulic cement often contains additives to accelerate curing and enhance water resistance. While this might seem advantageous for aquarium use, the trade-offs include reduced strength and increased susceptibility to cracking compared to mixes strengthened with sand or other aggregates.

- Strength and Cracking Issues: When used without appropriate aggregates, hydraulic cement’s inherent weakness leads to more prone cracking structures. This vulnerability is exacerbated in water-rich environments like aquariums, where consistent exposure can further challenge the integrity of the material.

- Misconceptions About Portland Cement: “Portland cement” encompasses a wide range of products, leading to confusion about its properties and suitability for DIY rock projects. Variations in cure times, the presence of contaminants, and pH stability are significant concerns that can impact the health of aquatic life and the durability of the created structures.

- The Case for Low Alkalinity White Cement: Brands like Riverside White Cement are specified for their low alkalinity, crucial for maintaining pH balance in aquarium environments. The lower alkalinity reduces the risk of pH spikes that can harm aquatic life. Despite its advantages, the recommendation of specific brands or types like low alkalinity white cement often meets resistance, primarily due to higher costs and limited availability compared to more common hydraulic cements.

- Cost and Availability Concerns: The reluctance to use specialized cement types such as low-alkalinity white cement stems from their higher cost and less widespread availability. This has led to a preference for more readily available, though less suitable, cement types, contributing to challenges in achieving stable, durable structures within aquariums.

Types of Cement Safe (non-toxic aggregates) for Aquatic Life

Portland cement

A fundamental material in the construction of DIY aquarium rocks, Portland cement is renowned for its durability and strength. However, opting for versions without added chemicals or harmful additives is imperative when selecting this cement for aquarium use. The pH of Portland cement naturally aligns with marine environments once cured and properly leached, making it a staple choice for aquarists aiming to mimic natural reef structures.

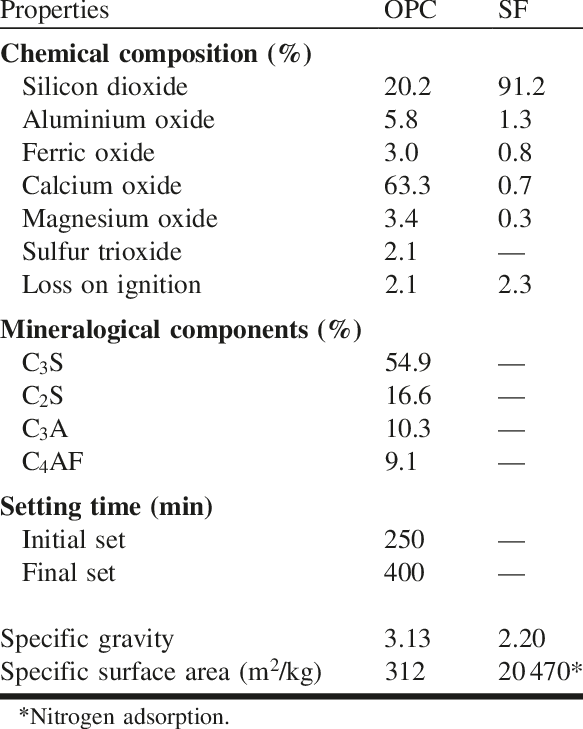

Portland cement’s suitability for aquarium environments stems from its chemical composition and hydration properties. Made primarily from calcium silicates, Portland cement includes

With minor amounts of other elements. When mixed with water, the key components, C3S and C2S, undergo hydration to form calcium silicate hydrate (C-S-H) and calcium hydroxide (CH), crucial for the cement’s hardening and strength development. While initially generating heat, this process stabilizes, making the material suitable for constructing durable and stable structures in aquariums once fully cured and leached to remove excess lime, ensuring safety for aquatic life.

Five types of Portland cement are standardized in the United States by the American Society for Testing and Materials (ASTM):

- Ordinary (Type I),

- Modified (Type II),

- High-early-strength (Type III), l

- Low-heat (Type IV),

- Sulfate-resistant (Type V).

Type II is omitted in other countries, and Type III is called rapid hardening. Type V is known in some European countries as Ferrari cement.

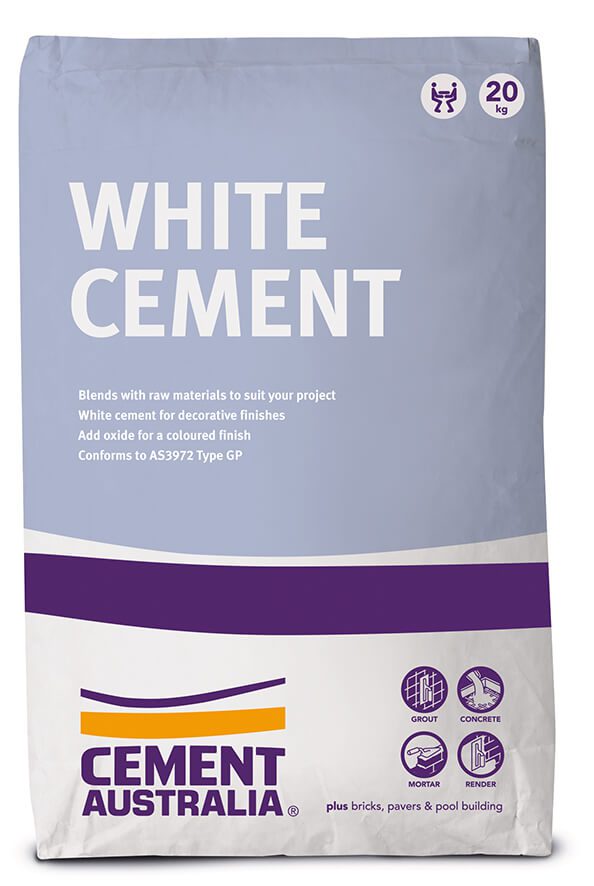

White cement or White Portland Cement

Preferred for its aesthetic appeal, white cement offers a lighter base colour, ideal for creating vibrant and visually appealing rocks. Like Portland cement, white cement must be chosen carefully to ensure it’s free from toxic additives. Its finer texture allows for more detailed sculpting, and when combined with non-toxic colourants, it can produce stunning, life-like rock formations that enhance the beauty of any aquarium.

White cement is distinguished by its high degree of whiteness, achieved through substantial modifications in the manufacturing process, including using high-quality limestone with low iron content and reducing other impurities. This type of cement requires a higher sintering temperature (1600 to 1700°C) than ordinary Portland cement due to the higher melting point of the mix depleted in iron oxides.

The meticulous control of elements such as chromium, manganese, and iron oxide (keeping them below specific percentages) is crucial to maintaining their colour and safety in aquarium environments. These adjustments contribute to the aesthetic qualities of white cement and ensure that it does not adversely affect the delicate balance within a reef aquarium.

White Portland cement’s composition typically includes calcium oxide (CaO) at 65-70%, silica (SiO2) at 20-25%, alumina (Al2O3) at 3-8%, and iron oxide (Fe2O3) at a notably lower range of 0.5-2.5%, among other components. This careful formulation minimizes the potential for harmful effects in an aquarium setting, making it a preferred choice for constructing decorative and safe structures within marine habitats.

Its applications extend to architectural concrete, decorative and precast concrete, masonry, and tile adhesives, showcasing its versatility and aesthetic appeal. Despite its advantages, cost, availability, susceptibility to staining, and longer curing times are essential when choosing white cement for aquarium projects.

Cement types to Avoid for your DIY Aquarium Rocks

When creating DIY aquarium rocks for aquariums, selecting suitable cement types is crucial to ensure the aquatic environment’s safety and health. Based on the information gathered, here are cements that you should avoid using in your DIY aquarium rock projects:

- Modified or Polymer Modified Cement: These types of cement contain additives that may not be safe for aquatic life. The additives can alter water chemistry or leach harmful substances into the aquarium. Sticking with plain Portland cement products is recommended, as they are generally considered aquarium-safe after proper curing.

- High-Alkali Cements: Cements with high alkali content can lead to significant shifts in pH and are not recommended for use in aquarium settings. Always check the composition and opt for low-alkali options.

- Cement with Toxic Additives: Any cement that includes toxic dyes, chemicals, or other additives that could leach into the water should be avoided. While some dyes like red oxide (iron oxide) are considered safe once the cement has cured, caution should be exercised, and it’s generally safer to avoid coloured cement unless you are confident of their composition and safety.

- White Cements (with caution): While not strictly to be avoided, white cements often require longer to cure pH stability compared to ordinary Portland cement. This means they may take much longer before they’re safe to introduce into an aquarium. If choosing white cement for aesthetic reasons, ensure it’s appropriately cured and tested before use.

- Cement Containing Harmful Heavy Metals: Some cement may contain trace amounts of heavy metals, which can be toxic to aquatic life. Always ensure the cement you select does not contain harmful metals like chromium, lead, or mercury.

Importance of Aggregate Selection

Non-toxic aggregates

The selection of aggregates is critical for the safety and stability of your reef aquarium DIY. Aggregates should be inert, meaning they do not react chemically with the aquarium’s water parameters. Common choices include washed sand, crushed coral, or aragonite sands, which are safe and can help maintain the aquarium’s pH balance. It’s essential to avoid aggregates that contain metals, chemicals, or other substances that could leach into the water and harm aquatic life.

Natural vs. synthetic aggregates

When choosing between natural and synthetic aggregates, consider both the environmental impact and the specific needs of your aquarium. Natural aggregates, such as coral sand or volcanic rock, can offer beneficial minerals and maintain a more stable pH.

On the other hand, synthetic aggregates are often more uniform in size and shape, allowing for a more consistent texture in your DIY projects. However, they must be carefully selected to ensure they are safe for aquariums and free from any coatings or substances that could dissolve in water.

For anyone planning a DIY aquarium project, selecting the correct type of cement is crucial. Ensure you opt for plain Portland cement and avoid those with harmful additives or characteristics that could impact the health of your aquarium environment. Always follow proper curing processes and conduct thorough research or consult with experts before starting your project.

Additives and Colourants: Enhancing Aesthetics Safely

Creating a visually appealing and structurally sound underwater landscape requires more than mixing cement and water. Including certain additives and colourants can significantly enhance the aesthetics and durability of your eco-friendly aquarium rocks, making your aquarium a captivating display of artistry and nature.

However, safety is paramount; every material introduced into the aquarium must be non-toxic and safe for aquatic life. Let’s explore achieving this balance with the proper additives and colourants.

Safe Additives for Structural Integrity

Fibers for reinforcement

One way to enhance the structural integrity of your cement rocks is by incorporating fibres into the mix. Synthetic fibres, such as polypropylene fibres, are often used in construction for their strength and resistance to cracking.

However, for aquarium use, natural fibres can offer a safer alternative. These fibres disperse throughout the cement, creating a matrix that improves tensile strength and reduces the risk of fractures. Importantly, ensure that any fibres used are safe for marine environments, posing no risk to aquatic inhabitants.

Steel Fibers

Steel fibres are widely recognized for improving structural strength, reducing crack widths, and enhancing durability, impact, and abrasion resistance. They can also improve the freeze-thaw resistance of the concrete. Steel fibres sometimes replace traditional steel reinforcement (rebar), especially in industrial flooring and precasting applications. This makes them a strong candidate for constructing durable and resilient aquarium structures that require minimal maintenance over time.

Polypropylene and Nylon Fibers

Polypropylene and nylon fibres improve mix cohesion and enhance concrete’s permeability over long distances. They also contribute to the concrete’s resistance to freeze-thaw cycles, spalling in severe fires, and plastic shrinkage during curing.

Additionally, these fibres improve the concrete’s impact and abrasion resistance, reduce the necessity for steel reinforcement, and help control crack widths more effectively, ensuring a more durable structure. Their use can be particularly beneficial in creating complex shapes or designs for aquarium rocks, where flexibility and durability are paramount.

Macro Synthetic Fibers

Macro synthetic fibres offer an alternative to steel fibres, providing nominal reinforcement and suitable for aggressive environments like marine and coastal structures. They are handy for their non-corrosive properties and can be used in applications where reducing the concrete’s ecological footprint is a priority.

Micro Synthetic Fibers

Microsynthetic fibres effectively control plastic shrinkage cracking and improve the concrete’s toughness. They are suitable for applications where fine detailing or intricate texturing is required on the aquarium rocks, as they do not significantly alter the concrete’s workability.

When selecting fibres for reinforcement, consider the specific requirements of your aquarium structure, such as the desired appearance, structural load, and environmental conditions. Steel fibres offer high strength and durability, making them suitable for load-bearing structures.

Polypropylene and nylon fibres, while enhancing durability and reducing cracking, might be more appropriate for non-load-bearing decorative elements where flexibility and resistance to environmental degradation are key. Macro and micro synthetic fibres provide tailored solutions for specific durability and ecological considerations.

Natural bonding agents

To further improve the cohesion and durability of your cement rocks, consider adding natural bonding agents. These substances can help bind the cement and aggregate particles more effectively, reducing porosity and enhancing the overall solidity of the structure.

Examples of natural bonding agents include certain types of clay or finely ground pozzolanic materials like volcanic ash. These materials improve the rock’s integrity and maintain a safe environment for the aquarium’s ecosystem by ensuring that no harmful chemicals are released.

Using Colorants for Natural-Looking Rocks

Iron oxide pigments

For those aspiring to achieve the most authentic look possible, iron oxide pigments offer a palette of earthy tones that mimic the hues of natural rock formations in marine environments. Available in shades of red, yellow, brown, and black, these pigments can be carefully mixed into your cement to create varying colours and patterns.

Iron oxide pigments are prized for their colour stability, resistance to fading under lighting used in aquariums, and, most importantly, their safety for marine life. A little goes a long way when using these pigments, so start with small amounts and gradually adjust to achieve the desired colouration.

Non-toxic dyes

In addition to pigments, water-based, non-toxic dyes can offer a broader spectrum of colours, allowing for more vibrant and diverse rock formations. These dyes should be specifically labelled as safe for use in environments with live plants and animals.

It’s crucial to integrate the dye uniformly throughout the cement mixture to ensure consistent colouration and to prevent any leaching of colour once the rocks are submerged. Experimentation with dyes requires careful consideration of the potential impact on water quality and the health of aquarium inhabitants, underscoring the importance of selecting products certified as aquarium-safe.

The Role of Water in Mixing Cement for Aquarium Use

Achieving the Right Consistency

Water-to-cement ratio

The water-to-cement ratio is a critical factor in preparing cement for aquarium use, impacting both the workability of the mix and the strength of the final structure. A ratio of approximately 0.45 to 0.50 parts water to 1 part cement by weight is often recommended for aquarium structures.

This ratio ensures that the cement mix is not too runny, which could weaken the structure, nor too thick, making it difficult to mold and shape.

To achieve a uniform consistency, start by adding most of the water to the cement and aggregates, then gradually add the remaining water until the desired consistency is reached. Use a mechanical mixer or a sturdy mixing tool to ensure that the ingredients are thoroughly combined, eliminating dry pockets that could lead to weak spots in the finished structure.

Mixing techniques for uniformity

Mixing should continue until the cement has a smooth, moldable consistency similar to thick oatmeal. This texture is ideal for sculpting and will hold its shape during the molding and curing. For larger projects or those requiring finer detail, adjustments to the water-to-cement ratio might be necessary, with slight increases in water for improved workability or decreases to enhance structural integrity.

pH Considerations and Adjustments

Before introducing any cement-based structure into an aquarium, it’s crucial to consider the potential impact on water pH. Fresh cement tends to be highly alkaline, with a pH exceeding 12, which harms most aquatic life. To ensure marine compatibility, the pH of the water used in the cement mix should be as neutral as possible, ideally close to 7.0. After curing, the structure should be soaked in water for some time, with frequent water changes to leach out excess alkalinity.

Testing water pH

Testing the pH of the soaking water daily with a reliable aquarium pH test kit is essential. Continue this process until the pH stabilizes, usually within the range of 7.0 to 8.2, which is suitable for most marine and reef aquariums.

This leaching process can take several weeks, depending on the size and density of the structure. For aquarists looking to expedite this process, adding a mild acid such as vinegar to the soaking water can help neutralize alkalinity more quickly.

However, this must be done cautiously, with regular pH testing to avoid swinging to the opposite extreme of acidity.

Adjusting pH for marine compatibility

Adjusting the pH for marine compatibility is a critical step in ensuring the long-term health and safety of the aquarium inhabitants. Once the structure’s pH matches the intended aquarium environment, it can be safely introduced to the tank.

Regular monitoring of the aquarium’s overall pH is advisable to ensure a stable and healthy environment for all aquatic life, especially in the weeks following the introduction of new cement structures.

Environmental Considerations and Sustainability

Creating a reef aquarium that mimics the natural environment of marine life requires an artistic touch, technical skill, and a deep commitment to environmental sustainability. The materials we choose and the methods we employ can have a lasting impact on both the micro-ecosystem of our aquariums and the broader natural world. This section will delve into making eco-friendly material choices and understanding their effects on water quality and marine life, ensuring our underwater landscapes promote long-term sustainability and minimize ecological footprints.

Eco-Friendly Material Choices

Recycled aggregates

Incorporating recycled aggregates into your DIY cement rocks is a step towards sustainable aquascaping. For instance, using crushed glass or recycled ceramic as part of the aggregate mix diverts these materials from landfills and provides an inert quality safe for aquatic environments. A recommended ratio for mixing might be 1 part cement to 2 parts sand, with up to 30% of the sand portion replaced by recycled aggregates. This blend ensures the structural integrity of your creations while embracing eco-friendliness.

Sustainable sourcing of materials

Opting for locally sourced materials reduces the carbon footprint associated with transportation. When selecting cement and aggregates, aim for suppliers who practice sustainable mining or manufacturing processes. For colourants, prioritize natural or organic compounds that offer safety and environmental benefits. The choice of materials reflects our commitment to the health of our aquarium’s inhabitants and the planet’s well-being. Whenever possible, verify the sourcing practices of your suppliers to ensure they align with sustainability standards.

Impact on Water Quality and Marine Life

Long-term sustainability

Using eco-friendly materials in aquarium structures supports the long-term sustainability of marine ecosystems. By choosing pH-neutral or easily balanced components, we can avoid drastic shifts in water chemistry that stress aquatic life. For example, ensuring the cement’s alkalinity is neutralized through thorough curing and leaching processes—typically soaking the finished structures in water and changing it daily over 3-4 weeks—helps maintain the stability of the aquarium’s environment.

Minimizing ecological footprint

Every choice made in the construction of aquarium landscapes carries an ecological footprint. We can significantly reduce this impact by selecting sustainable materials and employing environmentally conscious construction practices. For instance, using a lower cement ratio in mixes, such as a 1:3 cement-to-aggregate ratio, reduces resource use and produces lighter, more porous rocks conducive to marine life. Additionally, opting for energy-efficient curing methods, like natural air drying, further decreases the overall ecological footprint of our aquascaping projects.

Tips for Selecting and Sourcing Quality Materials

practical strategies for identifying reliable suppliers and conducting quality checks before purchasing, ensuring that your DIY cement rocks look natural and fostering a healthy environment for your aquatic life.

Identifying Reliable Suppliers

Local vs. online suppliers

The choice between local and online suppliers often hinges on cost, quality, and availability. Local suppliers offer the advantage of direct inspection of materials and immediate availability, which is crucial for small-scale or urgent projects. However, they might have a limited selection compared to online suppliers, who can offer a wider variety of materials and sometimes better prices due to lower overhead costs. When choosing online suppliers, look for those with transparent sourcing practices, comprehensive product descriptions, and positive customer reviews. Websites like Home Depot or Lowe’s can be reliable sources for basic materials like Portland cement and aggregates. At the same time, specialized online retailers such as Bulk Reef Supply provide products suited explicitly for reef aquariums.

When sourcing materials, consider the delivery logistics, especially for heavy items like cement and aggregates, where shipping costs can significantly affect the overall price. For local suppliers, building a relationship can lead to insights on the best materials for your projects and potentially negotiate better prices.

Quality Checks Before Purchase

Ensuring purity and safety

The purity of the materials is paramount to avoid introducing harmful substances into your aquarium. For cement, ensure it’s labelled as ‘pure’ or ‘natural’ Portland cement without additives or extenders. For aggregates, opt for natural, inert materials like quartz sand or crushed coral, less likely to affect water chemistry adversely.

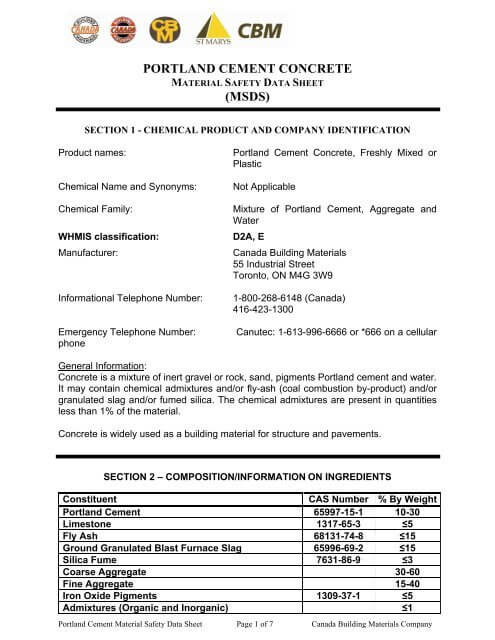

Certifications and standards

Look for materials that meet relevant environmental and safety standards. For instance, the ASTM International standards for Portland cement (ASTM C150) ensure that the cement meets specific chemical and physical requirements suitable for marine use. Additionally, seek suppliers who can provide Material Safety Data Sheets (MSDS) for their products, offering detailed information on chemical composition, hazard identification, and safety measures.

Summary

In our exploration of creating a captivating and sustainable reef aquarium, selecting and sourcing suitable materials for DIY cement rocks has been thoroughly examined. This article provided essential insights into choosing safe and appropriate cement and aggregates, balancing the benefits of local versus online suppliers, and the critical process of conducting quality checks to ensure the materials’ purity and safety.

Emphasizing the significance of material standards and certifications, such as ASTM International standards for cement and the necessity of reviewing Material Safety Data Sheets (MSDS), readers are equipped with the knowledge to make informed decisions that prioritize the health of their aquatic ecosystem and its aesthetic appeal.

As we advance to the next stage in our series, “Design and Planning Your Aquarium Landscape,” we will shift focus towards the creative aspects of constructing your reef aquarium. This forthcoming article will delve into strategies for designing and planning rock shapes and arrangements that enhance the beauty of your aquarium and create a conducive environment for marine life.

It will cover techniques for sketching out your designs, considering the needs of different aquatic species, and planning your aquascape to support a vibrant and healthy marine ecosystem. Stay tuned for expert tips and ideas to help visualize and execute a stunning underwater landscape in your reef aquarium.